In-Mold Decorations: Integrating Style and Manufacturing Excellence

In-Mold Decorations: Integrating Style and Manufacturing Excellence

Blog Article

Grasping In-Mold Decorations: Techniques, Patterns, and Finest Practices for Optimal Results

In the realm of production, the art of in-mold decorations stands as an essential element of product layout and production. As sectors consistently look for innovative methods to enhance aesthetic charm and functionality, understanding the intricacies of in-mold decors has become a crucial capability. From picking the right materials to incorporating advanced layout patterns, the trip in the direction of attaining optimum cause this domain name is multifaceted. By delving into the approaches, fads, and ideal practices that underpin successful in-mold design procedures, services can unlock a realm of possibilities that not only elevate the visual appeal of their items however likewise streamline manufacturing efficiency and boost consumer interaction.

Product Choice

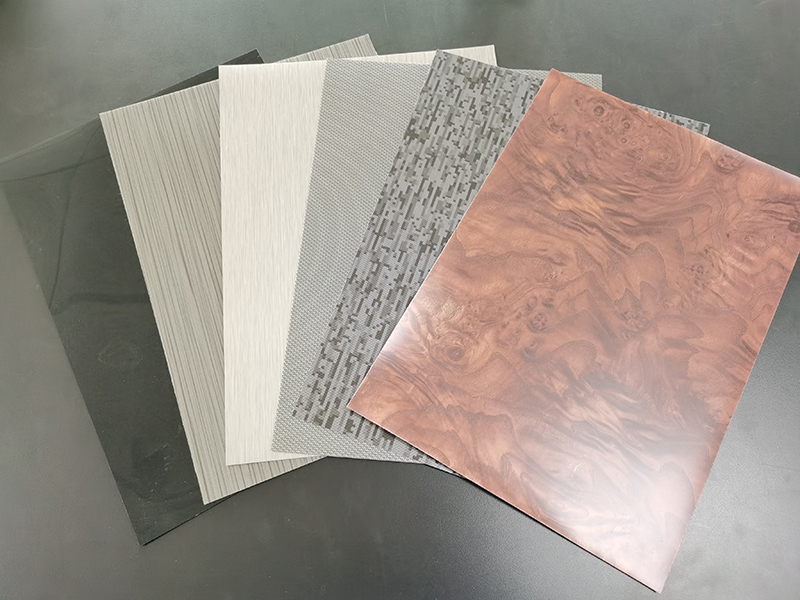

Product option is an important aspect of mastering in-mold decors, as it directly affects the top quality and longevity of the last product. When picking products for in-mold designs, it is crucial to take into consideration aspects such as compatibility with the molding procedure, the preferred aesthetic outcome, and the ecological conditions the item will certainly face.

Additionally, the selected product must possess good attachment buildings to guarantee that the decor sticks firmly to the substrate throughout the molding procedure. Adhesion between the decoration and the material is vital for avoiding delamination and making certain long-lasting visual allure. Furthermore, products with high warmth resistance are preferred for in-mold decorations, particularly for items that will be exposed to raised temperatures during their lifecycle. By meticulously selecting the ideal product for in-mold decors, makers can boost the overall quality and durability of their products, meeting the expectations of both end-users and clients.

Style Advancement

A vital consider advancing the field of in-mold decorations is the continual exploration and application of style development techniques. Layout technology plays a critical role in enhancing the visual allure, performance, and overall quality of items made using in-mold design processes. By including ingenious design components, manufacturers can differentiate their items on the market, attract customers, and stay in advance of rivals.

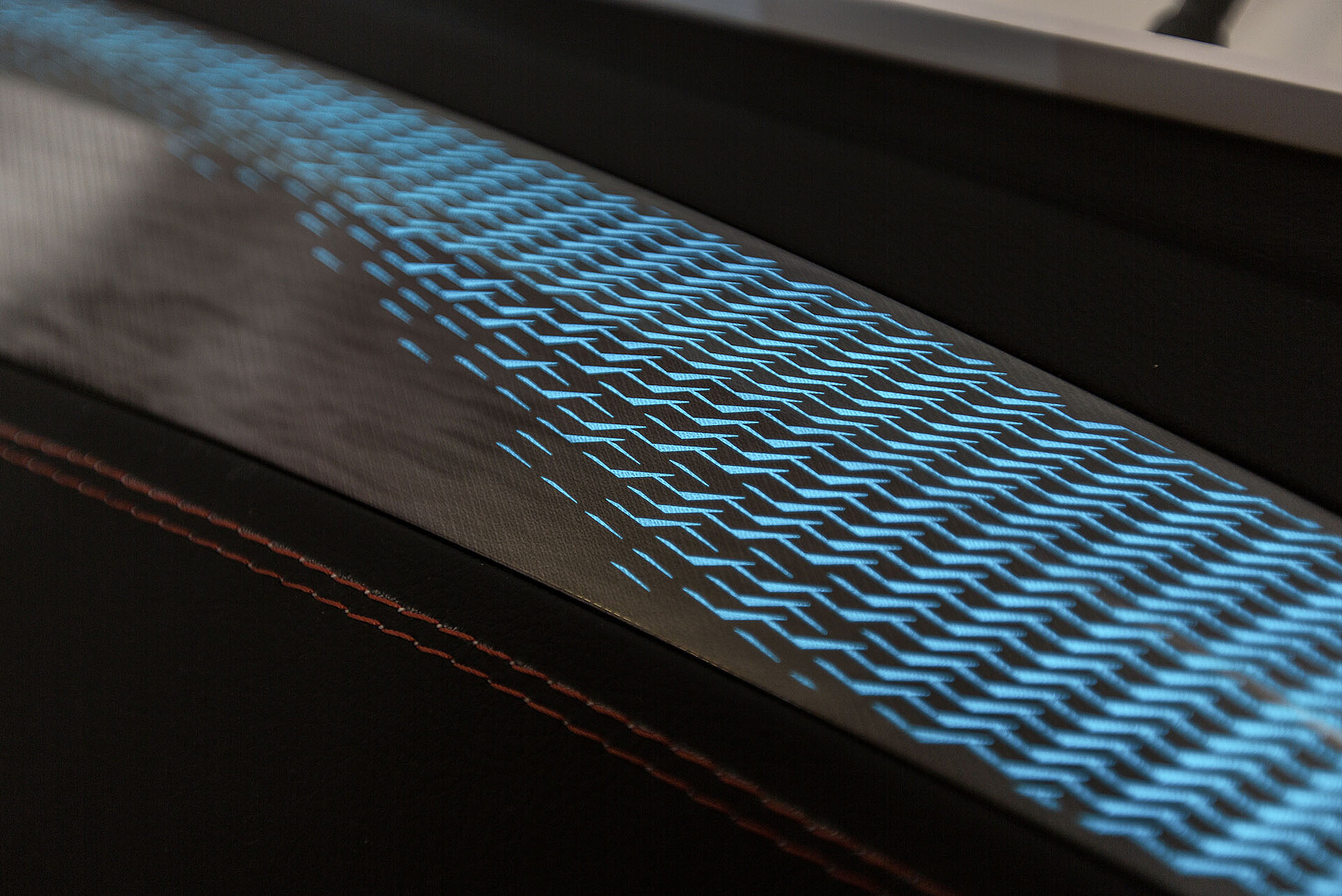

One of the crucial aspects of layout advancement in in-mold decorations is the integration of intricate patterns, appearances, and graphics that were previously testing to accomplish with typical design techniques. Advanced innovations such as 3D printing and digital style devices allow developers to produce facility and in-depth designs that can be flawlessly transferred onto shaped parts. Furthermore, using dynamic shades, metallic surfaces, and unique impacts like gloss or matte appearances can even more elevate the aesthetic appeal of in-mold embellished items.

Additionally, layout innovation prolongs beyond visual appeals to incorporate functional enhancements such as ergonomic forms, incorporated features, and customizable aspects that cater to certain customer needs. By embracing layout development, producers can unlock brand-new opportunities for personalization, creative thinking, and item differentiation in the competitive landscape of in-mold decors.

Manufacturing Performance

Effective production procedures are necessary for equating the ingenious designs created in the area of in-mold decorations right into top notch completed products that fulfill market demands and consumer assumptions. In the realm of in-mold designs, manufacturing efficiency encompasses various crucial aspects that add to the total success of the manufacturing process.

In addition, carrying out automation and robotics in the production line can substantially enhance performance by enhancing repetitive jobs and decreasing the margin of mistake. Automation not only speeds up the manufacturing procedure but likewise enhances accuracy and repeatability, leading to an extra consistent and top notch output. Embracing lean production principles, such as just-in-time stock monitoring and waste reduction techniques, can better enhance production effectiveness by minimizing downtime and maximizing resource usage. Generally, a holistic method to production effectiveness is extremely important in maximizing the capacity of in-mold design strategies and attaining optimal outcomes in the competitive market landscape.

Quality Assurance Procedures

What are the vital techniques for ensuring strict top quality control actions in the realm of in-mold designs? Quality control procedures are vital in in-mold decor procedures to make sure the manufacturing of top quality and perfect completed products.

Using innovative modern technologies such as automatic evaluation systems Read Full Article can also improve the high quality control process by providing precise and dependable data for evaluation. These systems can discover imperfections that may be missed out on by hand-operated evaluations, consequently boosting overall product top quality and uniformity.

Routine training and growth programs for employees included in the in-mold decor procedure can likewise add to maintaining premium criteria. By educating staff on best methods, high quality assumptions, and the importance of interest to detail, business can cultivate a society of top quality awareness throughout the organization.

Consumer Appeal

To improve the marketability of in-mold look at this web-site decor products, understanding and providing to customer preferences play an essential function in determining their charm discover this and success. Offering customization choices such as customized designs, shade variants, and textural aspects can significantly boost the appeal of in-mold decor items.

Conclusion

In-mold designs supply a functional and reliable way to boost item looks. Grasping in-mold decorations requires a holistic strategy that thinks about all elements of the production procedure to guarantee success.

In the realm of production, the art of in-mold designs stands as a critical aspect of item style and manufacturing. Style development plays an important function in boosting the visual appeal, capability, and overall top quality of products manufactured making use of in-mold design processes.One of the vital aspects of layout development in in-mold decors is the combination of intricate patterns, structures, and graphics that were previously testing to achieve with typical design approaches.Reliable production procedures are important for converting the innovative layouts developed in the area of in-mold decorations right into premium ended up products that satisfy market needs and consumer assumptions. Offering personalization options such as individualized layouts, color variations, and textural components can significantly improve the allure of in-mold decor products.

Report this page